Vernon Her Manufacturing and Industrial Enterprises

Taken from

The Vernon Banner - 1873

Vernon Hub and Spoke and Wheat Fan Factory

February 5, 1873

Owned and conducted by Messrs. Robert Leavitt and James A. McClelland, under the firm name of R. Leavitt & Co. This is

decidedly a live institution, with live men at the head of it.The establishment consists of the following buildings:

1. A main shop, 25 x 50 feet, three stories high; with an L, 25 x 65 feet, two stories high.

2. An engine room, with iron roof, 12 x 30 feet.

3. Two ware houses, 25 x 50 feet, two stories high.

4. One ware house, 30 x 40 feet, one story high.

5. One ware house, 20 x 40 feet, one story high.

Making the aggregate of 13,355 feet of floor space; besides which they use a part of the depot building for storage of manufactured articles, and find themselves still cramped for room.

The propelling power is a splendid engine of 30 horse power, full capacity of boiler.

The machinery on the first floor of the main building consists of two spoke lathes, each turning about 800 spokes per-day, one double circular saw, for cutting off both ends of the spoke at once - two sand belts for smoothing spokes, one throater and one tenoning machine.

On the second floor-one planer, one hub boring machine, to mortising machines, two circular saws, two turning lathes, one hub hewing machine, one grooving machine, one tenoning machine, one car machine, one gaining machine, one matching machine, one iron planer, one grinder (with apparatus especially adapted to grinding bite for planers). The second floor is mainly used for the fan department.

The third floor is used for bending felloes, shafts, tongues and bows, and is supplied with all necessary steam boxes, machines and forms for the purpose.

Dusters are provided for carrying away the dust from the sand belts, saws and the cuttings from the planners conducting them directly to the furnace.

The establishment is capable of manufacturing 360,000 spokes, 600 to 800 sets of hubs, felloes, etc., per year and has orders ahead of its capacity. It is also capable of turning out 2,000 wheat fans per year. (A wheat fan was a machine used to separate the wheat from the chaff after it was harvested. They were made mostly of wood.)

The stock of wagon and carriage wood work now on hand, turned, finished and seasoned, consists of-oak spokes, 50,000; hickory felloes, 1,200 sets; oak felloes, 1,000 sets; buggy hubs 700; wagon hubs 1,300. For all of which the firm has orders abroad, to be shipped as fast as corresponding material can be supplied and transportation obtained.

Besides the manufactured articles on hand the yards are stacked with immense quantities of timber, in the rough, for spokes, hubs, felloes, etc.

All the materials used in the products of this establishment are directly drawn from the people of our own county, and all its earnings, wages and profits, expended among mechanics, laborers and farmers.

In 1875 this business was destroyed by fire, it was rebuilt and running again in September of 1876.

The Vernon Stave and Heading Works

February 12, 1873

Owned and conducted by Will S. and Smith K. Vawter, under the firm name of Vawter and Vawter. The proprietors of this establishment,

although both are young, are men of energy, ability and business tact. And are deserving of much credit for the perfection to which they have brought their

machinery, and the sagacity displayed in establishing a new business in which neither had any previous experience, on a paying business in so short a

time-the works having been in operation but little more than one year.The site of the establishment is that of the old Woolen Mills of Newton & Schofield, on the bank of the Muscatatuck, north of the J. M. and I. railroad, and east of Pike Street. The dimensions of the main building are 32 x 90 feet, two stories high, with engine room in the basement, in addition to which there is a warehouse, 36 x 55 feet, and a shed for storage 20 x 120 feet, and eight feet high, for stacking staves, a cooper shop, for making barrels in which to ship heading, detached steam boxes, dry houses, etc.

The engine which drives the machinery is of 30 horse power; the boiler is 30 feet in length by 40 inches diameter.

The machinery used is one 50 inch drag saw; one splitting saw, 48 inches, one heading saw, one circular machine, one head jointer, one planer, one stave cutter, one equalizer, one barking machine, two foot stave jointers, grindstones, with attachments especially adapted to grinding planer bits, machine knives etc. The establishment is also provided with a McClelland Duster for carrying away planer shavings, saw dust, etc.

The rapidity with which the native timber is out of our forest, from the rough log simply cut into suitable lengths, is transformed into excellent cooperage, is truly wonderful to the novice. The steam boxes for steaming stave blocks contain twenty cords, which are steamed during the night, and furnish material for 20,000 staves - the work of one day (ten hours) for the stave enterprises. The heading saw has capacity to cut 5 cords of timber, making 6,000 pieces of heading per day. The circling machine will circle 1,200 sets of heading (7,200 pieces) per day.

The capacity of the dry kiln, for seasoning is 15,000 staves and 25,000 pieces of heading.

To run this machinery thirty hands are needed, to say nothing of those indirectly employed in getting out and hauling timber.

The amount of capital employed is $12,000, which the proprietors inform us is wholly insufficient to carry on such an establishment with the most profitable results.

The firm has orders beyond its ability to fill. The extreme severity of the winter has operated discouragingly, interfering with the running of machinery and preventing receipts of material, so that the demand of their products are far in excess of supply, but with the probability of fairer weather the prospects brighten.

Like the establishment previously mentioned, the materials used in this enterprise are purchased from the people of our own county, its profits and the earnings of its employees expended among the merchants and farmers of our own vicinity and its proprietors are therefore worthy of all the encouragement the community can bestow.

Vernon Wagon, Pump and Hay Rake Factory

February 26, 1873

This establishment, owned and managed by Messrs, Adolphus G. Cotton and Thomas B. Reed, under the firm name of Cotton & Reed, is

located at the junction of the J. M. & I. Railroad with Perry Street.The buildings consist of one 115 x 30 feet - consisting of a wood shop for wagon work, blacksmith shop (2 forges). Machine shop and Engine room-a paint shop 20 x 30 feet, Varnish room and office 14 x 20 feet and a storage room 30 x 40 feet.

The machinery propelled by steam consists of two large lathes, with automatic apparatus for turning rake heads and teeth, but also applicable for general turning; one upright boring machine; one horizontal machine for boring pump stocks and piping ; one saw; and one planer. In addition, the firm design, as soon as practicable, to put in a jig saw and some other needed machinery. This machinery is propelled by an eight horse power engine-which being insufficient for their purposes, the firm design soon to replace with a larger one.

In addition to the above machinery the firm have all the necessary hand power machines for wagons to be made and a general blacksmithing business, including a tire bending and "upsetting" machine, hand power upright drill, boring and tenoning machine for felloes (wood rim) and spokes, hub boring machines etc.

The pump and rake machinery is capable of turning out the wood work for fifty horse hay-rakes per day, or between fifty and one hundred pumps per day.

In the wagon and carriage and general blacksmithing department the firm are doing custom work and repairing exclusively.

Mssrs, Cotton and Reed are both comparatively young men-industrious, enterprising, and excellent citizens, who are fully deserving of all the patronage and encouragement it is in the power of our citizens to bestow, so their establishment is one of the ones of productive industry, contributing to the prosperity and general wealth of the community.

The McClelland Duster and Conveyor

March 5, 1873

This useful machine, the invention of Mr. James A McClelland, one of our citizens is rapidly growing in popularity, and in fact is regarded

almost indispensable in factories where circular saws and planers extensively used, besides which it is being furnished or rather introduced for other purposes-such

as forcing heated air from furnaces into dry kilns, blowing dust from grain chutes, etc, to which it is equally applicable.The territorial right for several States, including those of Indiana and Kentucky, was purchased from the inventor by Geo. C. Westover and Smith K. Vawter; in the year 1869, who, under the firm name of Westover & Vawter; proceeded to put in operation one duster in each of the principal factories in the several larger cities and towns in Indiana and Kentucky. The apparatus was at first made, excepting the fan, entirely of wood, but the proprietors realizing the advantages to be gained from a stronger and more durable machine got up patterns for an improved exhaust blower, made all of iron, and the improvement has been found to give general satisfaction.

On the first of January, 1872, Mr. James P. Westover purchased the interest of Smith K. Vawter, since which time the business has been conducted under the firm name of Westover & Bro.

Up to Jan. 1, 1873, there have been sold and put in operation, of the old wooden pattern, fifty dusters, amounting to $8,994.00, and of the improved iron pattern forty-seven, amounting to $7,350.00.

A part of the castings and machine work are made by Sinker, Davis & Co., of Indianapolis, and a part by Busch & Son, of Columbus. The Dusters are completed and put together here, by Mr. Wm. Osborne, a superior workman and the prince of good fellows, who connects this business with his cabinet making; and hence the machines are shipping to their destination.

The following are some of the most prominent establishments using this Duster and Conveyor: The Ohio Falls Car Company at Jeffersonville (one of the largest car building establishments in the United State); the Louisville & Nashville Railroad Shops, at Louisville, Ky.; Studebakers Bros. Manufacturing Co., at South Bend, Ind. (one of the most extensive wagon factories in the West); The Singer Sewing Machine Factory has four fans carrying the dust and shavings from sixty wood working machines; and the Duster & Conveyor is also used by the Howe Sewing Machine Company at Peru, Ind.

Vernon Woolen and Flouring Mills Company

February 19, 1873

This is a joint stock Company, organized for the purpose of carding, spinning and manufacturing wool into rolls, yarns of woven goods, either for

customers who prefer having the raw material worked up for their own use, or for purchase, manufacture and sale by the Company, and also for custom or merchant grinding

of four and meal.The principle officers of the Company are Jacob L. Doll , President, and Thomas T. Walker, Secretary and Treasurer.

The building occupied is the old Branam hotel stand, situated at the junction of Pike Street with the J.M. & I. railroad and is a large substantial brick, admirably adapted to its present use.

The propelling power is a 40 horse power engine, sufficient not only to run the present machinery, but a full additional set, which the Company desire to put in should the public demand seem in future to warrant it.

The machinery and apparatus for present use, in the wool department, consists of;

One complete set of 48 inch manufacturing cards, one set of 24 inch double roll cards, one picker; one 240 spindle spinning jack; one twister; four looms for weaving blankets, flannels, cassimeres, satinette, jeans, tweeds, and indeed every description of woolen goods usually manufactured in this part of the country; one napping machine; one sheering machine; one warping mill; one fulling mill, dye house, etc.

With the machinery now in use, this Company has the capacity to work up 40,000 pounds of wool per annum.

The grinding apparatus for the manufacture of flour and corn meal, consists of two run of the mill stones of Northdyke & Co,'s make, said to be the best in use for custom work-one for wheat and one for corn-together with the necessary bolts, smut mills, elevators, sinks & etc. to form a complete custom and merchant mill, with capacity to grind ten to twelve bushels of wheat and twenty to thirty bushels of corn per hour.

The capital invested for building and machinery alone amounts to about $20,000.

The Company have now on hand a large stock and excellent assortment of woolen goods and yarns for the accommodation of customers, and are taking all the wool and all the grain offered them, at highest cash prices.

This establishment is one worthy of all the encouragement and patronage it is in the power of the people of our county to bestow - because it adds to our aggregate wealth and prosperity, furnishes employment for those who would be compelled to seek it elsewhere, furnishes a convenient market for the surplus products of our farmers, thereby stimulating increased production, and supplies them with articles of necessity for which their means would be sent abroad and lost to the community.

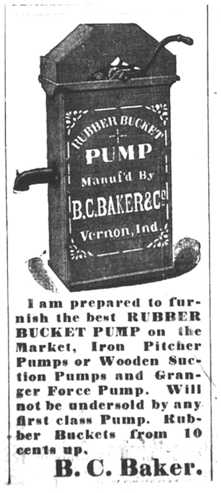

Ben C. Baker

March 19, 1873

Among the enterprising businesses of Vernon, none are perhaps more worthy of favorable notice than the gentleman above mentioned. He is a man of

multifarious employments, of indomitable will and unflagging energy; but strictly honorable and upright in all his dealings. While we have never seen him charged with

unfairness or of taking dishonorable advantage in trade, it is a common saying with those who know him that what Ben Baker cannot sell it is useless for anyone else to

try.While it is true, as we before said, that Baker is a man of multifarious employments-a general trader, in fact, dabbling in almost any kind of business that comes to his hand-his particular "hold" is in the sale of horse hay rakes and wooden pumps.

The proprietor, by purchase, of the "Butler patent hay rake," (the invention of Manlove Butler, one of our own citizens), he has said, sold over portions of the territory of Indiana, Kentucky, Michigan, Illinois, Missouri and Kansas, during the past five years, upwards to ten of ten thousand rakes and anticipates the sale of at least one thousand the present season. The rake, wherever introduced by Mr. Baker sells rapidly. His plan of introducing the implement is to go into a neighborhood where other rakes are used, cut the harvest field and rake against the competitor. Therefore he finds no trouble in making sales.

This makes it therefore possible for this rake to take first premiums at several State and numerous county fairs.

In connecting counties with the foregoing, we previously intimated, Mr. B. also sells and Improved Wooden Pump-an improvement of his own invention, and acknowledged by those using it to possess superior merit. Of those he has sold upwards of five hundred. Three hundred were sent to Illinois alone last year.

Until recently, Mr. Baker has been engaged in the manufacture as well as the sale of the rake and pump, but finding both branches of the business too complicated for one man to attend to efficiently, he sold to Messrs. Cotton & Reed (some notice of whose establishment we gave in a former article), his machinery and transferred the business of manufacturing to them, proceeding to confine his own energies to introducing and making sales of rakes, pumps and territory.

The business Mr. Baker is engaged in is that of kind which abides to the prosperity of the community. The articles sold are made almost exclusively of home material-their manufacture given remunerative employment to a number of hands, and by their sale thousands of dollars are yearly added to the general wealth of this locality.

An Advertisement for the Baker Pumps taken from the February 1891 Banner Plain Dealer newspaper.

You may use this material for your own personal research, however it may not be used for commercial publications without express written consent of the contributor, INGenWeb, and